Medical braces and assistive wearables serve critical functions in supporting mobility and aiding individuals with temporary disabilities. However, these devices often lack aesthetic appeal and fail to provide personal expression, leading to psychological challenges and social stigma. We propose a novel fabrication method, Fabric-Lego, which combines 3D-printing with traditional garment-making (pattern-making, sewing, ironing, and overlocking) to address these shortcomings. By integrating customizable Lego®-like blocks into wearable fabrics in accessible DIY ways, users can personalize their wearables while maintaining comfort and functionality. W e present the fabrication process, including insights on materiality, pre-processing, 3D-printing, and post-processing steps. To demonstrate the design space and potential applications of our method, we implemented 3 prototypes: 1) a customizable arm sling cover, 2) a customizable fnger splint cover, and 3) a T-shirt with integrated blocks. This approach offers a promising path for enhancing the user experience and empowering individuals to embrace their unique identities.

This research is published at DIS ’24 here: https://doi-org.proxy.queensu.ca/10.1145/3656156.3663705

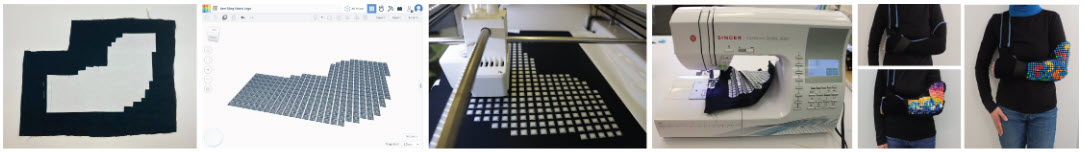

Our Fabric-Lego fabrication method of integrating 3D-printing with traditional sewing practices to create customizable

garments and assistive wearables.

The fabrication process of the Fabric-Lego arm sling: (left to right) from the sewing pattern and 3D-model design to3D-printing and post-processing sewing, showing wearing the arm sling with and without the customizable Fabric-Lego cover.

The fabrication process of the Fabric-Lego fnger splint: (left to right) from sketching the sewing pattern and designing the 3D model, to 3D-printing, machine-sewing and customizing based on personal preference.

The fabrication process of the Fabric-Lego T-shirt (left to right) from the sewing pattern and 3D-model design to 3D-printing and pose-processing sewing, serging, and ironing, showing wearing the T-shirt.

Acknowledgement of Funding

This project was funded by the National Sciences and Engineering Research Council of Canada (NSERC) through a Discovery Grant (2021-04135), its Discovery Supplementary Fund (2021-00310), as well as through a Queen’s Research Initiation Grant (RIG). We acknowledge the support of Ontario Research Fund and Canadian

Foundation for Innovation for this research.