Hybrid crafts are increasingly repurposing the metal materials used in hand crafts for their conductive and interactive affordances. In this paper, we look to the history of metal threads and their use in the fine craft of bobbin lace to explore tensions and opportunities for leveraging bobbin lace techniques with e-textile crafting. First, we

contribute an overview of the history of metal thread use in bobbin lace practices. Second, we provide insights on contemporary bobbin lace culture from individual interviews with 17 bobbin lacemakers. Third, to better understand how to integrate e-textiles with bobbin lace practices, we engaged in a Research-through-Design process of creating e-textile bobbin lace patterns and samples alongside two group feedback sessions with members of a bobbin lace guild. Together, these three contributions provide an introduction of the affordances and constraints of bobbin lace as a unique fabrication method for e-textile hand crafts.

This research is published at TEI ’25 here: https://doi-org.proxy.queensu.ca/10.1145/3689050.3704957

In this paper, we explore opportunities for e-textile bobbin lace with three contributions: (1) summarizing the metal thread history of bobbin lace for HCI audiences, (2) conducting interviews with contemporary bobbin lacemakers to understand their craft practices, and (3) creating e-textile bobbin lace samples with iterative feedback from members of a bobbin lace guild. Images courtesy (left to right) of the Smithsonian [15 ], Kathy Morgan, and potentiometer sample created by the research team.

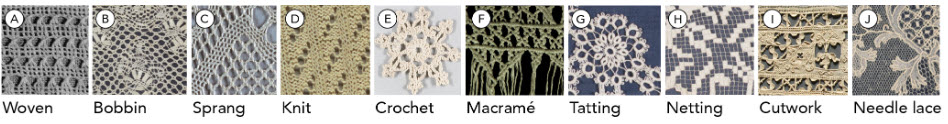

Laces are textiles defined by their negative spaces. Examples of lace fabrication techniques include (a) woven lace [16], (b) bobbin lace [6 ], (c) sprang [8], (d) knit lace [22 ], (e) crochet lace [12], (f) macramé [4 ], (g) tatting [11 ], (h) netting [ 13], (i) cutwork [3], and (j) needle lace [7]. Images courtesy of the Smithsonian and The Metropolitan Museum of Art.

Making bobbin lace involves three phrases: (1) preparing the bobbins and pricking the pattern, (2) working the pattern by interlacing and pinning, and (3) finishing by tying off the threads and unpinning the pattern.

To make bobbin lace there are core tools including (a) bobbins, (b) pins, (c) scissors, and (d) pillow. There are also supplementary tools including a (e) pricker, (f) pusher/puller, (g) crochet hook, and (h) bobbin holder.

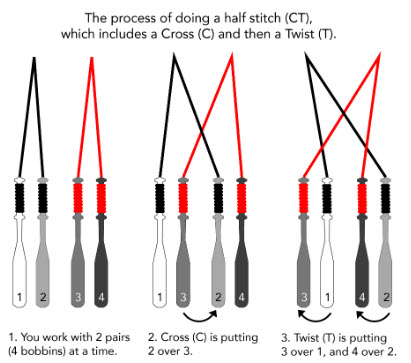

Bobbin lace stitches are made by working with 2 pairs (4 bobbins) at a time. Bobbin lace stitches are made from two stitch components: Cross (C) and Twist (T). Here we show the process of making a “half stitch” (CT).

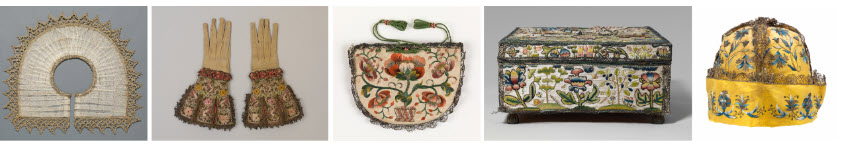

Examples of accessories with bobbin lace edges made of metal thread including: a collar [ 5 ], a pair of gloves [1 ], a purse [10], a embroidered box [2], and a nightcap [9]. Images courtesy of the MET Museum and the Smithsonian.

Today lacemakers play with materials and scale to bring bobbin lace to new applications, such as (left to right) (a) glow-in-the-dark threads, (b) yarn to create scarves, (c) wire to create sculptures, and (d) wire to create jewelry. Images courtesy of (left to right) Jenny Lyn Albers, Kathy Morgan, Veronika Irvine, and Josée Poupart

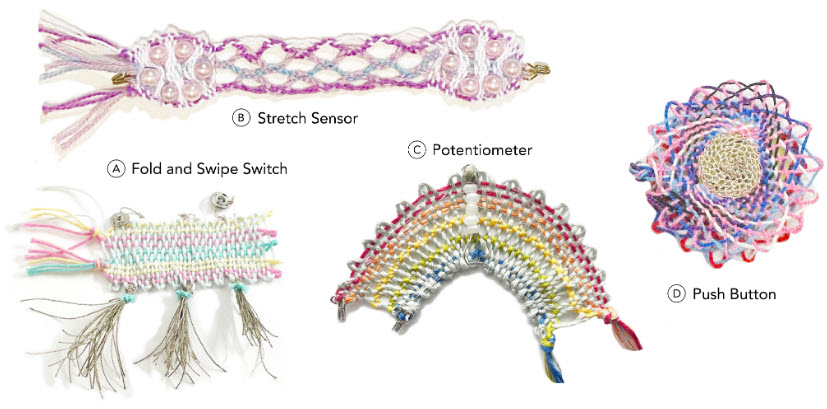

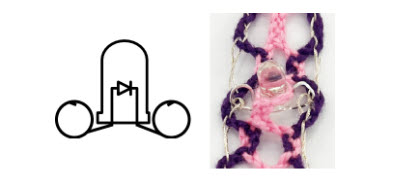

Some interactive e-textile patterns from A-Kit-of-No-Parts [ 105] that we transformed into bobbin lace patterns for guild feedback including (a) fold and swipe switch, (b) stretch sensor, (c) potentiometer, and (d) push button. Along with lace stitches, we also used other parts such as the conductive tassels for the swipe switch, beads in the stretch sensor, a long string of beads for the wiper in the potentiometer and wire to hold the structure, and sponge between two layers for the push button.

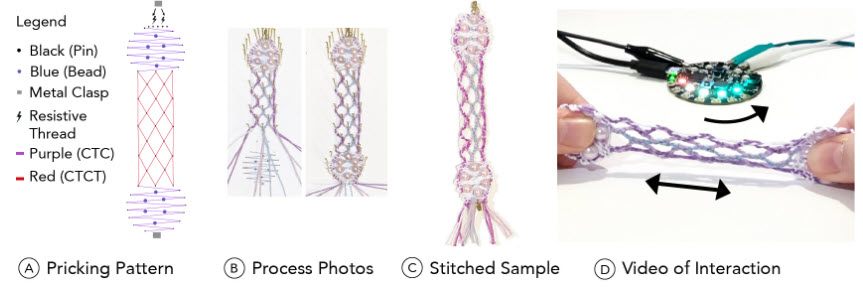

For each sample, we provided the following items for guild feedback: (a) bobbin lace patterns, (b) images with steps of the creation process, (c) photos of the final stitched sample, and (d) videos of the sample in action with an explanation of how it worked. This series shows the pattern, creation, and interaction of a bobbin lace stretch sensor with variable resistance thread

To transform LEDs into “beads” that could be laced, we curled up the LED’s two “legs” into circular bead shapes. The smaller the circular hole, the better it held in place. Lace-makers recommended making the hole the same diameter as the thread or material you are using.

Predicting where threads will go can be difficult with bobbin lace. As a first step, we leveraged more predictable stitch types such as passive threads in CTC stitch and parallel zigzags with CTCT.

Acknowledgement of Funding

We would like to thank our study participants, and the members of the Hinterland Lacers Guild, who generously contributed their time to share and discuss their bobbin lace practice with us. This project was funded by the National Sciences and Engineering Research Council of Canada (NSERC) through a Discovery Grant (2021-04135), its Discovery Supplementary Fund (2021-00310), as well as through a NSERC Postdoctoral Fellowship Award. We acknowledge the support of Ontario Research Fund and Canadian Foundation for Innovation for this research. Lee Jones was able to take bobbin lace courses thanks to a grant from the Ontario Arts Council.